Protruding head correct blind bolt grip is a 02 since grip range of 02 maxibolt is 094 to 154.

Blind bolt specifications.

No reduction in diameter to allow for the slot is required.

In combined tension and shear blind bolts should satisfy the following expressions.

The thin wall bolt has a strong shear capacity.

This extended grip capacity of 025 under minimum grip to 025 over maximum grip for a total of 100 with no composite damage and joint performance still in excess of guaranteed minimums makes the composi lok iia one of the most tolerant blind fasteners for composites on the market.

For a complete list of testing criteria and load ratings download the box bolt catalog.

Blind flange dimensions class 150 to class 2500 outer diameter of body bolt circle bolt hole diameter straightness and alignment of the bolt hole thickness of the blind.

The first blind fastener to achieve icc testing and approval the esr 3217 approval document has been published on the icc web site.

W 5 32 nominal diameter cherry maxibolt blind bolt 219 min.

In addition the fasteners are available with an optional drive washer.

Blind flange dimensions class 300 400 600 900 1500 2500 up to 24 inch asme b16 5 with stud bolts requirements bolts diameter.

After installation a neat low profile head is left with no stud.

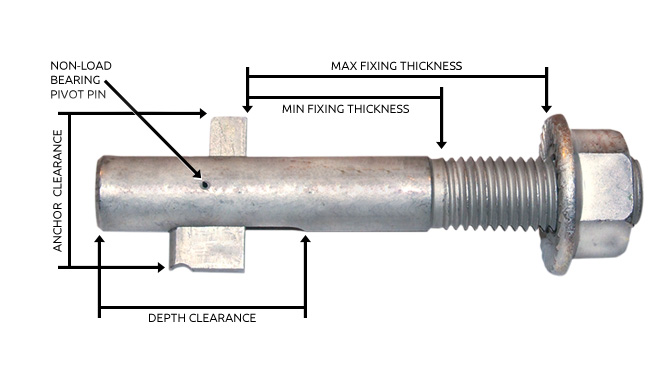

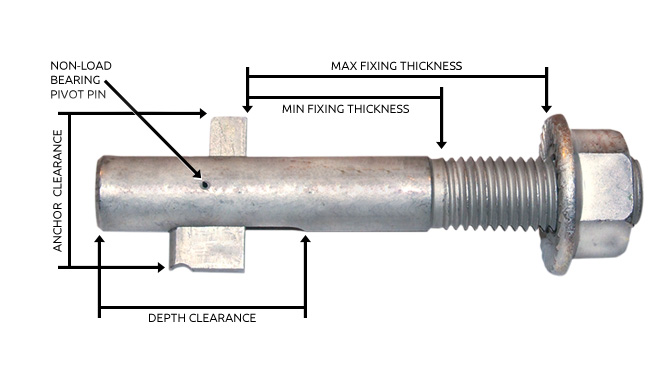

During installation the 3 basic components are locked together and work as a single unit to carry shear tension and vibration loads.

In bearing the resistance of a blind bolt should satisfy the requirements of aisc specification 360 10 clause j3 10 expressions j3 6a or j3 6b as required using the nominal diameter d of the bolt.

The huck unimatic blind bolts are pull type high strength blind fasteners consisting of a hollow sleeve a spindle or pin and a lock collar.

Grip with blue anodize on sleeve.

95mm 135mm 175mm 250mm made in u s a.

Superior structural strength nexgen2 m20 bolt astm 490m high tensile steel coil spring shear sleeve astm a519 grade 4140 magni coated complete assembly available lengths.

The tw or thin wall bolt was developed to address the need for a blind fixing to be used into lightweight steel sheet or cladding material.

Machine countersunk read correct blind bolt grip to the top of the sheet.